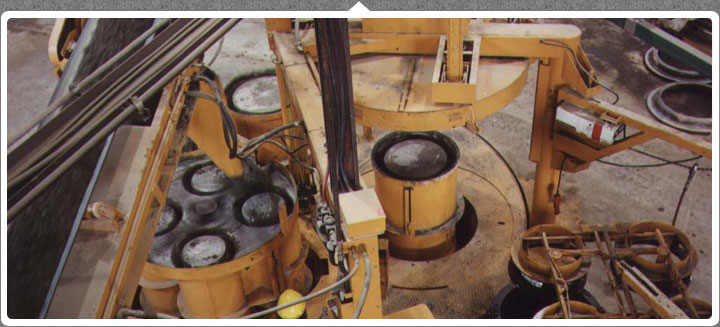

Concrete Pipe Machine (PipePlus 96)

- The world’s most productive concrete pipe machine, capable of producing more than 100 pipes/hour in the smaller dimension ranges and capable of single-handedly serving the world’s largest markets.

- The PipePlus 96 machine combines versatility, wide production range, high output and simplicity into one outstanding package. With its three station rotary design, the PipePlus96 will produce pipe in numbers never-before achieved. Three different pipe sizes are produced at the same time using small diameter EightPak molds, SixPack molds, Quad molds, Duo molds or Single molds depending on the diameter of pipe produced. Additionally, a quick fifteen-minute changeover time further enhances manufacturing flexibility and permits short production runs of special or lower volumn products. The PipePlus 96 from conrete pipe machine manufacturers uses the time proven vibration under pressure process to manufacture concrete pipe in sizes 300mm (12″) to 2500mm (96″) in lengths up to 3.5M (12′).

-

- EightPak modules up to 450mm (18″)

- SixPak modules up to 600mm (24″)

- Quadform modules up to 800mm (30″)

- Triform modules up to 900mm (36″)

- Dualform modules up to 1200mm (48″)

- Single forms up to 2500mm (96″)

- Maximum pipe length of 3.5m (12′)

- 15 minute mold changeover

- PLC-equipped with automatic pressheading and vibration controls in addition to an automatic, swipe – style, filling system

Concrete Pipe Machine Features & Benefits

-

- 3-Station Turntable Principle

- Exact length products

- Header System

- Synchronized Core Vibration (SCV)

- Multiforms

- Quick Mold Changeovers

- Semi-Automatic Operation w/ optional Smartchute

- Optional Cast-in-place manhole steps

- Optional lifting anchor automation

3-Station Turntable Principle of Concrete Pipe Machine

Telescope your production processes for maximum efficiency A traditional concrete pipe machine has (3) major processes – first the mold is filled, second the filled mold is pressed with a spigot former and finally the pipe is demolded. Utilizing the 3 Station principle, all these processes happen at the same time – multiplying the productivity!!

Exact length products

Remove product variability by ensuring each product is exactly the same length. Many concrete pipe production machines are unable to accurately control the length of their products. Through a mixture of volumetric fill control, a proprietary pressheading process and precision mold quality, the PipePlus eliminates this inconsistency.

Header System

Produce pipe with perfectly round,glass-like spigots ensuring exact field pipe connections Use of stay-in place headers allows for the production of pipe with more precise male-end spigots with a smoother surface finish.

Synchronized Core Vibration (SCV)

High-powered, built-in, electrically driven core vibration system allows for the production of high quality pipe and eases form changeover. In a SCV system, every form set has its own, built-in vibration system. The use of such a system gives the added benefit of eliminating the need to swap vibrators from core to core during changeover, eliminating the costly downtime and increasing plant flexibility.

Multiforms

Easily multiply your production tonnages through the use of patented Multiforms. The PipePlus machines allow for the possibility of mass-production through the use of the Multiform system – allowing the producer to increase his output by 2x, 3x, 4x, 6x and even 8x – without significantly affecting cycle times.

Quick Mold Changeovers

Be Flexible. Don’t tie up your money in excess pipe inventory. Simple, machine to-mold connections and self-contained mold modules allow for changeovers of less than 15 minutes on the PipePlus machines.

Semi-Automatic Operation w/ optional Smartchute

Automate to save labor and achieve precisely repeatable production cycles, guaranteeing each product is as high quality as the next The PipePlus machines can be equipped with optional automatic presshead and vibration controls as well as a concrete distribution chute that automatically adjusts between pipe dimensions.

Optional Cast-in-place manhole steps

Eliminate costly & back breaking labor required to drive steps into manhole products The Cast-in-place step (CIPS) program allows for the automatic casting-in of manhole steps – including an automated step insertion robot to keep machine operator working at a safe distance from the machine.

Optional lifting anchor automation

Save labor costs by automatically casting lifting anchors into products during machine cycle. One of the most tedious and labor-consuming tasks in a manhole or pipe operation is the insertion and driving in of lifting anchors into already-cured products. Eliminate this step with an automated lift-anchor insertion system.