Quality and Innovative Concrete Pipe Manufacturing for Great Returns

With the increasing demand in concrete products, it has become crucial for all builders to align themselves with professional and competent manufacturers who will deliver quality and quantity as required. Apollo HawkeyePedershaab Concrete Technologies Pvt. Ltd (AHCT) is one of the best manufacturers for these products in India.

Concrete Pipe Facts for Industrial and Civil Works

The concrete pipe has been in existent for a long time since its invention. There have also been numerous efforts in quality improvements that have made it what it is today. Most of the applications are external, used in conveyance of storm water and sewerages worldwide.

Application of Concrete Pipe Machine in Construction of Drainage Systems

The circular and reinforced concrete pipe is a highly recommended product for construction of drainage systems, storm drains, culverts and even irrigation systems. This type of pipe shows good strength and performance properties and is also cost effective compared to other drainage construction materials.

Choosing the Best Pipe Making Machine for Perfect Sewage: A Brief Overview

Facilitating a gamut of industrial operations, the concrete pipes are one of the most durable, economical and versatile conduit materials.

Application of Concrete Making Machines in Infrastructural Development Projects

Roads, rail and infrastructural developments are the backbone of any nation’s economy. As the saying goes” do not marvel at the beauty of any building or construction but the foundation that will stand the test of time”. Roads require a number of structures such as bridges, culverts, storm water drainages, drainage systems, underground water passages and tunnels.

Cutting Edge Mould Making Machines with High Productivity and Low Maintenance

Concrete products such as blocks, pipes and materials have advanced infrastructure and the construction industry. The moulding process is an innovative and fast process of making culverts, drainage pipes, open channels, storm water, industry waste conveyance pipes and sewage lines.

Global Demand of Concrete Pipe Making Machine

The recent technological breakthrough in the industry of concrete machinery is one of the reasons for the growth of construction industry. This is one of the leading industries in the global market. There is hardly any country in the world where the business of construction is not experiencing the maximum growth in the present days.

Emerging Markets for Concrete Pipe Machines in Different Continents

The global supply of concrete pipe machines is still way below the demand as indicated from usage of concrete pipes. Pre cast concrete pipes are different from the convectional pipes in that for precast; the manufacturer has far greater control on the design and manufacturing process than casted pipes. Consequently, there has been a lot of interest in concrete pipe making machines and demand is growing rapidly.

Cage Welding Machine – All About Types & Advanced Technology

The use of automated cage welding machine is very common in various industries where high-class welding of pipes and other instruments is frequently required. These machines are mainly used for the production of wire cages. Among the top fields where such cages are used manhole and concrete pipe industry are the two major ones.

Important Facts about Concrete Making Machines

Well-designed concrete machines are not only efficient but also give quality and unique results. Some benefits of using the concrete machines include;

High Demand of Pipe Making Machines in Developing Countries

The demand of concrete pipes is mainly driven by the industries that consume them which are mostly the infrastructure projects. Despite the slowdown in construction activities in the period 2009 to 2014, there has been an upward trend again in the demand for the concrete pipes which in turn increases the demand for the Hume pipe making machines. Hume pipe making machines.

Cage Welding Machine - Importance in Manhole & Concrete Pipe Industry

Concrete pipes are rapidly gaining popularity in various areas of construction and infrastructural development. These pipes are used in making of manholes, sanitary sewer lines, storm drains, culverts and even in irrigation projects.

All About MBK Cage Welding Machines

The cage welding machine is used in manufacturing of reinforcement cages used in construction of manholes and concrete pipe manufacturing industry. Over time, MBK Company has become a global leader in manufacturing of the MBK cage welding machines.

Mould Equipment- Importance in Construction Industry

The mould equipment is used extensively in construction industry. The quality and rigidity of any concrete material depends on its mould. In short, better the mould, the better the quality of concrete material and longer its durability.

Role of Pipe Making Machine in Concrete Pipe Installation

The concrete pipes are used for water distribution and drainage system to certain extent throughout the world. Not all types of pipe can suit the required specification of users; thus, the producers require designing the structure of the pipe that can help the users for its proper installation.

Current Trends of Concrete Equipment Industry

The construction industry is one of the most significant industries in every country as it caters to the building of infrastructural facilities. Concrete is an integral part of this industry and so, processes for manufacturing concrete as well as using it have always been an area of research and development. In an era of automation, such processes require equipment to replace slow and error-prone manual tasks.

Demand and Process for Manhole Production System

Nowadays, there is a great demand for the manhole production system with the rise in population. In major cities, the subsurface teems with the utilities like sewers, drains, steam tunnels and utility corridors. This has increased the demand for the manhole production system.

Reasons and Best Fit to Choose Concrete Pipes

Concrete has been considered as one of the strongest and most durable material in the infrastructure development. There are different concrete pipes available that have economical and long lasting components of modern infrastructure.

Role of Concrete Machines in Infrastructure Development

Concrete machines have made the task of handling concrete much simpler and easier. This has made a big difference in the construction market and also inspired the construction of bigger and better buildings.

Global Rising Demand of Pipe Making Machine

A great deal of construction occurs on a daily basis and deals for new construction are made almost daily too. Some of these setups are small scale while some are large construction sites. The structure of a new project will usually involve planning, design, financing and finally execution.

Choose Concrete Pipes Manufactured from Pipe Making Machine

Pipes are an integral part of any construction project and have always been. Concrete material is being used since ancient times and has evolved and developed as technology progressed.

Diversifying the shape of Construction Through Mould Equipment

Construction is a tedious and wholesome process which utilises skill set from each and every department that it holds. Beginning from the layout to actual measurement on site and turning the structure drawn on paper to reality.

Installation of Concrete Pipes Through Reinforcements

Reinforced Concrete pipes are one of the standard materials used in sewer & sanitation systems, even for large irrigation projects. These modified concrete pipes not only offer high strength and durability at competitive costs but also acts as the primary alternative to high-density polyethylene pipes.

Variants of Concrete Pipes Changing the Future Construction

Concrete pipes have been in use for constructing all major structures across the globe. Non reinforced concrete pipe was used for the first time in culverts and sewers in the United States during the mid-1800s.

How to Choose the Ideal Wire Cage Welding Machine for Your Application

Wire Cage welding machine is one of the extensively preferred machines used in the production of round wire cages that may or may not contain socket. The machine mainly finds application in the construction industry as it provides one of the efficient means of achieving the task.

Why Concrete Pipes Are the Most Reliable Choice for Sewers

The Concrete pipes have been the most suitable choice for pipe system installation because of their durability. In most of the countries in the world, the engineers, contractors, and departments of the water drainage completely trust the concrete pipes and it has been a reliable option for more than a century.

Pre-stressed Concrete Pipes Types, Advantages & Features

Pre-stressed concrete pipes are used worldwide and they have emerged as the best replacement of steel pipes and RCC pipes.

FAQs on Concrete Pipe Making Machines

Concrete Pipe Making Machine is consolidated using Hydraulic Pressure as well as vibration. It is the best and most accurate method for the production of concrete pipes as per IS – 458. It is made using light weighed pieces of equipment and modern technologies.

Hume Pipe Making Machine Working Principle

There are many types of pipes available for various purposes. This includes the cast iron pipes, asbestos pipe, PVC pipes, galvanized steel pipes, concrete pipes, HDPE pipes, to name a few.

Role of Pipe Making Machine In Sewage Treatment

The pipe making machine is an equipment used for manufacturing concrete pipes. This procedure of manufacturing concrete pipes is also called Hume pipe manufacturing. In the process of creating pipes, cement has been used since centuries.

Concrete Pipe Making Machine - Progress Over The Years

Industrial equipment has improved a lot over the years, as every piece of equipment has adapted the high-tech technology and several features that are beneficial to execute different kinds of tasks easily.

All About Pressure Pipes

Pressure Piping is a set of pipes designed and constructed to contain a flow of fluid at high pressure. They have an assembly of pipes, pipe fittings valves, and accessories subject to internal or external pressure and can contain or convey fluid pressure.

Role of Pipe Making Machine in Manufacturing Cylinder Pipe

In any industrial setting it is very important to choose the material during the design phase to avoid incurring unnecessary costs and also to provide a seamless and smooth operation.

About Concrete Pipe Making Machine

Concrete pipe making machine is very useful in industry. Concrete pipe making machine can produce concrete pipes of any size. The pipe made with this machine is with superior quality and pressure capacity.

The Features and Benefits of a Concrete Pipe Machine

A concrete pipe machine can make any concrete pipe in any shape and size. The world’s most productive model is capable of producing 100 pipes per hour and can service the world’s largest markets.

Mould Equipment For Precast Concrete Products

For precast concrete products, mould equipment is a crucial component of the process. This machinery allows for precast concrete products to be manufactured to specific tolerances, including dimensional accuracy and surface finish.

CAP 150 Concrete Pipe Making Machine

The CAP 150/200 Concrete Pipe Making Machine is a versatile and reliable machine that uses a unique vibrated casting technology to produce seamless concrete pipes. The concrete pipe making machine comes with single or twin stations and has a wide range of features.

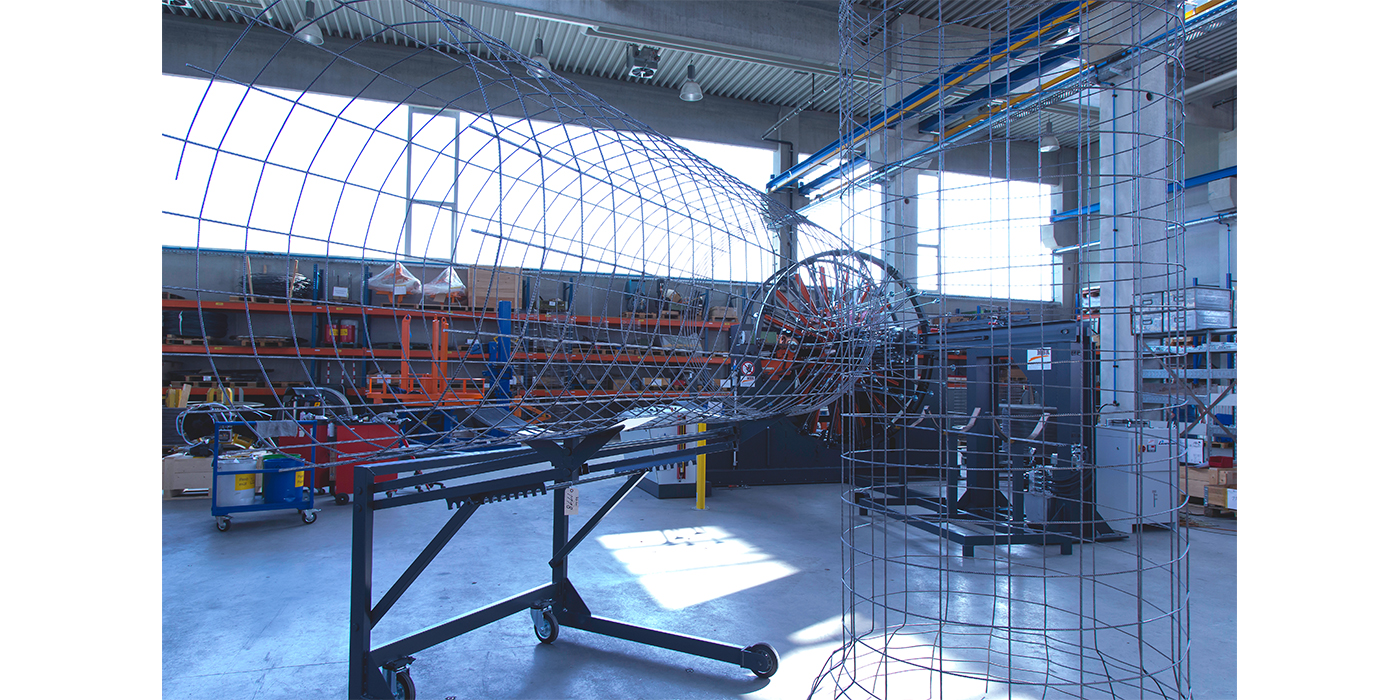

MBK Wire Cage Welding Machine ISM 250-R

MBK, a leading manufacturer of wire cage welding machines, focuses on innovative design. With short development cycles, the company can respond to new market requirements quickly.

Pre-Stressed Concrete Pipes (PCCP)

There are two types of prestressed concrete pipes: those with a steel cylinder core and those with a concrete core. The former are referred to as ‘cylinder pipes’ and those with longitudinal prestressing are known as ‘non-cylinder pipes’.

Advanced Technology and Future Trends in Concrete Pipe Making Machine

The manufacturing of concrete pipes, crucial for infrastructure such as sewage systems, stormwater drainage, and culverts, is experiencing significant technological advancements.

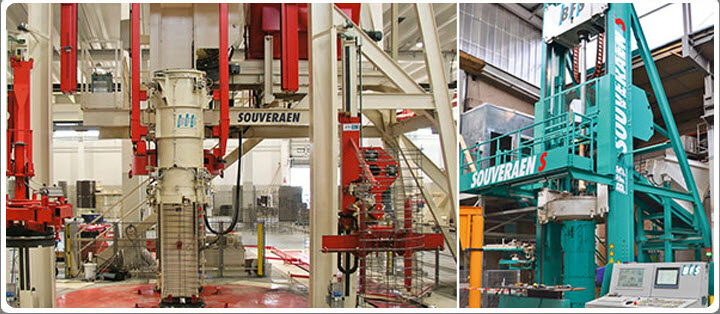

Souveraen (Packer Head Process): Revolutionizing Concrete Pipe Manufacturing

The Souveraen concrete pipe machine, utilizing the Packer Head Process, represents a significant leap forward in the realm of concrete pipe manufacturing.

Souveraen Technology Advantages in Concrete Pipe Manufacturing

The Souveraen technology in concrete pipe manufacturing marks a significant advancement in the industry, providing a range of benefits that enhance production efficiency, product quality, and environmental sustainability.

Karibic Revolutionizing Manhole Production with Fully Automatic Systems

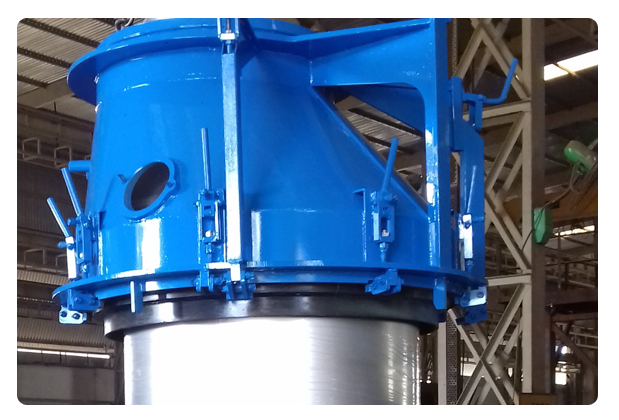

The Karibic system represents a revolutionary step forward in the field of manhole production, introducing fully automatic systems that streamline manufacturing processes, enhance product quality, and elevate efficiency to unprecedented levels.

Karibic Technology Advantages in Manhole Ring and Neck Production

Karibic technology is a groundbreaking advancement in the field of manhole production, specifically enhancing the manufacturing of manhole rings and necks. This technology integrates sophisticated automation and precision engineering to streamline processes, elevate product quality, and ensure sustainability.

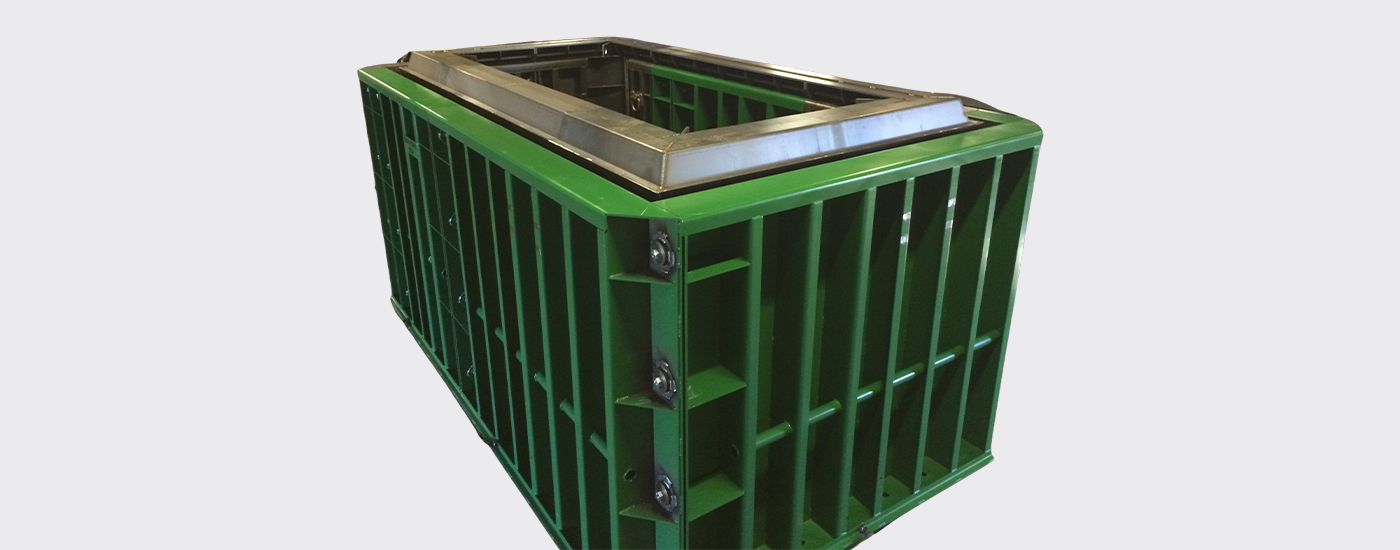

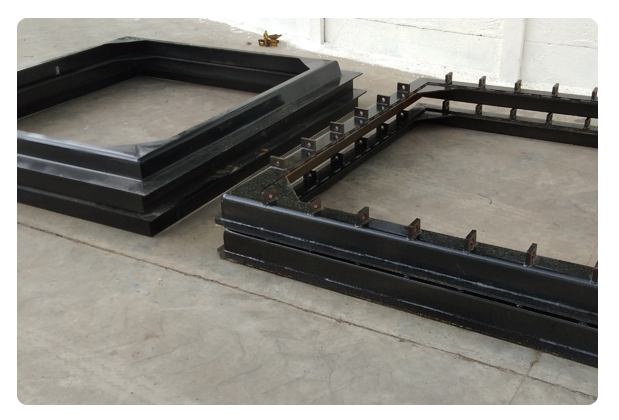

Drycast Moulds and Accessories: A Comprehensive Guide

Drycast moulds and accessories play a crucial role in the production of precast concrete products, offering precision, durability, and efficiency.

Karibic & Mammut for Manhole Rings/Bases and Box Culverts: Revolutionizing Prefabricated Concrete Products

The construction industry has long relied on prefabricated concrete products for their strength, durability, and efficiency. Among the key players in this domain are the Karibic and Mammut machines, which are designed for the production of manhole rings, bases, and box culverts.

Drycast Pipe Mould vs. Wet Cast Pipe Mould: What’s the Difference?

Concrete pipes play a crucial role in infrastructure, from drainage systems to sewage lines. The process by which these pipes are produced largely impacts their durability, cost, and time to market. Two primary methods used in the manufacturing of concrete pipes are drycast and wet cast moulding processes.

Drycast Pipe Mould Production Process: Step-by-Step Guide

Concrete pipes are essential for many infrastructure projects, including stormwater management, sewage systems, and drainage applications. One of the most efficient ways to manufacture concrete pipes is through the drycast pipe mould process.

KARIBIC’s Manhole Ring Production Process

KARIBIC’s state-of-the-art production line for manhole rings, necks, and bases is a model of modern engineering. With a focus on automation, this facility efficiently turns raw materials into high-quality, durable products designed for long-term use in infrastructure projects.

How MAMMUT’s Vibration Table Enhances the Production of Large Box Culverts

In the world of modern infrastructure, the demand for durable, large-scale concrete structures such as box culverts is ever-growing. These essential components play a critical role in drainage, sewage, and other utility networks, making the need for precision and durability paramount.

How Pipe Lifting Turning Yokes Enhance Productivity in Concrete Pipe Manufacturing

In the world of modern infrastructure, concrete pipes play a vital role in various construction projects, especially in drainage, sewage systems, and water management. However, manufacturing and handling these large, heavy pipes can be a time-consuming and labor-intensive process.

Lifting and Turning Heavy Concrete Pipes: Safety Tips for Using the LT-1400 and LT-2500 Yokes

Handling heavy concrete pipes during production, transportation, and installation requires specialized equipment to ensure safety and efficiency.

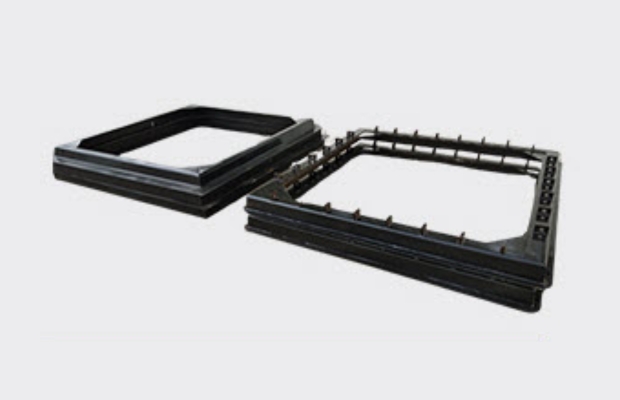

Why Wetcast Forms are the Future of Manhole Construction in India?

Manhole construction is a critical component of urban infrastructure, enabling access to underground drainage systems, sewage networks, and utilities. Traditionally, manholes in many parts of India have been constructed using bricks and mortar, a labor-intensive and time-consuming process.

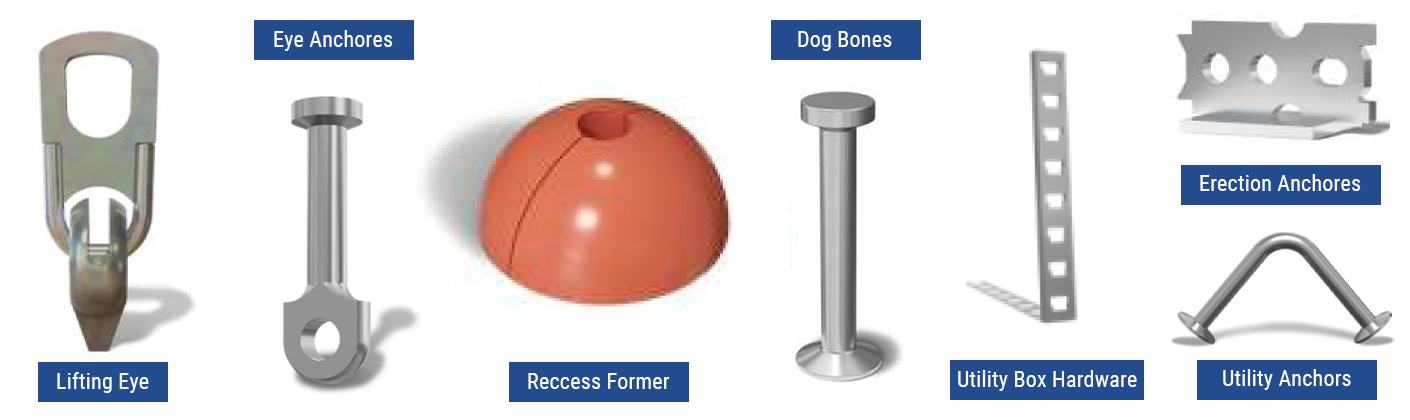

Precast Lifting Devices and Fasteners - Different Types and Applications

Precast concrete components are essential in modern construction, requiring reliable lifting and anchoring solutions for safe handling, transport, and installation.

The Science behind Concrete Curing Systems: How SmartSet Achieves Optimal Results

Concrete curing is a critical process that determines the final strength, durability, and overall quality of concrete products. The hydration process, requiring precise control of temperature, humidity, and water content, is fundamental to achieving these desired qualities.

Lifting Yoke Design Innovations: Trends in Modern Lifting Solutions

Lifting yokes are critical tools in heavy lifting applications, designed to support safe and efficient load handling in various industries, from construction and shipping to aerospace and manufacturing.

Drycast Mould Equipment: A Key to Building Resilient Infrastructure in Flood-Prone Indian Cities

India’s cities, particularly those near coastlines and riverbanks, are increasingly vulnerable to the impacts of flooding. With climate change exacerbating extreme weather events, urban centers like Chennai and Kolkata have faced repeated inundation.

The Role of Drycast Mould Equipment in India's Urban Development

India's rapid urbanization has placed significant pressure on its cities to modernize and build resilient infrastructure.

The Science Behind Reinforced and Non-Reinforced Concrete Pipes

Concrete pipes have been a cornerstone of modern infrastructure for decades, playing a critical role in drainage, sewage, and water management systems. The choice between reinforced and non-reinforced concrete pipes depends on the project's structural and environmental demands

The Role of Precast Manhole Systems in Modern Infrastructure Development

Manhole systems play a crucial role in urban and rural infrastructure, providing access points for maintenance, inspection, and servicing of underground utilities. The efficiency and durability of these systems largely depend on the quality of the manhole moulds used in their production.

Applications of Manhole Moulds in the Construction and Utility Sectors

Manhole systems are indispensable in urban infrastructure, providing access points for maintenance, inspection, and repairs of underground utilities. The production of these systems heavily relies on manhole moulds and advanced machinery, such as manhole producing machines and manhole making machines.

The Importance of Pipe Moulds and Applications in the Concrete Industry

The concrete industry is at the heart of modern infrastructure, producing critical components for construction, water management, and transportation. Among these components, concrete pipes are indispensable, serving as conduits for drainage, sewage, and utility lines.

A Step-by-Step Guide for Using Pipe Moulds in Construction Projects

Pipe moulds are essential tools in the construction industry, playing a crucial role in the production of concrete pipes used in infrastructure development. From drainage systems to irrigation projects, concrete pipe moulds ensure the creation of durable and precise components.

Pipe Pallet: A Game-Changer in Concrete Pipe Production Processes

The concrete pipe industry has seen significant advancements in recent years, with innovations aimed at improving efficiency, precision, and durability. Among these breakthroughs, pipe pallets have emerged as a revolutionary component in the production process.

Understanding the Importance of Box Pallet and U-Drain Pallets in Modern Construction Projects

In the ever-evolving construction industry, precision and efficiency are paramount. Components like box pallets and U-drain pallets play a crucial role in shaping modern infrastructure projects.

Concrete Pipe Making Machine Demand and Supply for Indian Cities

India’s rapid urbanization and infrastructure development have significantly increased the demand for efficient and durable construction materials. Concrete pipes are indispensable for infrastructure projects, including sewage systems, drainage networks, and water supply pipelines.

How Karibic Enhances Structural Integrity in Manhole Systems: Revolutionizing Manhole Rings and Bases

Manhole systems play a crucial role in urban infrastructure, providing access to underground utilities such as sewers and drainage systems. Ensuring the structural integrity of manhole rings and bases is essential for safety, durability, and efficient functionality

Mammut’s Precision Engineering in Box Culvert Manufacturing

Box culverts play a critical role in modern infrastructure. From roadways to drainage systems, their versatility and strength make them an indispensable component in construction projects worldwide.

How Concrete Pipe Lifting Equipment Improve Concrete Pipe Placement Accuracy?

In the world of construction, precision matters. When it comes to placing heavy concrete pipes, even the slightest miscalculation can result in costly delays, safety hazards, and compromised project quality.

Maintenance Tips to Extend the Life of Lifting Yokes

Lifting yokes are critical tools in construction and industrial applications, designed to lift, move, and position heavy loads safely and efficiently. These devices are invaluable when it comes to handling tasks that involve concrete pipes, precast units, or other heavy materials.

Applications of Automated Curing Systems in the Construction Industry

The construction industry is evolving rapidly, with automation playing a pivotal role in enhancing efficiency and precision. Among the many technological advancements, automated curing systems have emerged as a game-changer, especially in the realm of concrete production.

How Pressure Pipes Machinery Supports Large-Scale Projects?

In the world of infrastructure and industrial development, pressure pipes play an essential role. From water supply systems to oil transportation and sewage systems, pressure pipes are the backbone of many large-scale projects.

The Impact of Advanced Safety and Automation Features in Concrete Pipe Making Machines

Concrete pipe manufacturing has evolved significantly with the integration of advanced safety and automation features. These enhancements have not only improved worker safety but also increased production efficiency, precision and overall cost-effectiveness.

Drycast Moulds and its Accessories: The Key to Efficient Concrete Production

Concrete production is central to the development of infrastructure worldwide. Whether it's for water management, roads or sanitation, quality concrete products such as pipes, manholes and box culverts are essential to ensuring durable and efficient systems

The Role of U-Drains Mould in Precast Concrete Drainage Solutions

In modern construction, effective drainage systems are essential to ensure the longevity and safety of infrastructure.

The Role of Pressure Pipe Manufacturing Machines in Water Supply Projects

Water supply systems are one of the most critical infrastructures that support urbanization, agriculture and industrial growth.

Boosting Productivity with Dual Station Capability in Concrete Pipe Machines

Concrete pipe production is a vital component of modern infrastructure, supplying high-quality pipes for drainage, sewage and water management systems.

Importance of a Reliable Cage Welding Machine: From Design to After-Sales Support

Cage welding is a critical process in reinforcement steel production, playing a vital role in infrastructure and construction projects

The Role of Pneumatic and Automated Systems in Cage Welding Technology

The evolution of cage welding technology has transformed the way reinforcement structures are manufactured

The Role of Pipe Moulds in Reducing Defects in Concrete Pipe Manufacturing

Concrete pipes are widely used in drainage, sewage and irrigation systems.Their strength and durability depend on precise manufacturing processes and pipe moulds are central to achieving consistent, high-quality production.

The Connection between Pipe Mould Quality and Structural Integrity

Concrete pipes are fundamental to infrastructure, supporting drainage, sewage and water management systems.

Vertical Vibrated Casting for Concrete Pipes Quality Enhancements

Concrete pipes are essential for modern infrastructure. They are used in drainage, sewer systems and water transportation. The demand for high-quality concrete pipes is rising, making advanced manufacturing methods crucial.

How Advanced Concrete Pipe Machinery is Revolutionizing Manufacturing Efficiency?

The concrete pipe industry has seen major advancements in technology. Modern concrete pipe machinery now integrates automation, vibration control and precision engineering to enhance production efficiency. The latest concrete pipe making machines are faster, more reliable and produce high-quality pipes with minimal waste.

How High-Quality Pipe Moulds Improve Concrete Pipe Production?

Well-designed pipe moulds ensure that the final product meets strength and dimensional accuracy standards. They also impact production efficiency and cost. Choosing the right pipe mould manufacturers is crucial for consistent quality and long-term performance.

How Manhole Moulds and Box Moulds Shape Modern Construction Projects?

Manhole moulds and box moulds are essential in creating durable and efficient underground structures. They are used in the construction of sewer systems, drainage systems and other critical urban infrastructure. Without high-quality moulds, achieving consistent and reliable manhole structures would be nearly impossible.

Box Pallets & U-Drain Pallets: Essential Components in Modern Drainage Systems

Efficient drainage is critical for urban and industrial infrastructure. Box Pallets, U-Drain Pallets and Header Equipment form the foundation of modern drainage systems, ensuring smooth water flow and preventing flooding. Their structural design, durability and installation efficiency make them indispensable in stormwater management. This article explores their applications, benefits and innovations.

How to Keep Concrete Pipe Machine and Drycast Moulds in Top Condition? Maintenance Guide

Concrete pipes are essential in infrastructure projects, from drainage systems to sewage networks. Ensuring that concrete pipe making machines and drycast moulds function efficiently is critical for consistent production quality and cost savings. Regular maintenance can extend equipment lifespan, reduce downtime and optimize performance.

How to Match Your Concrete Pipe Making Machine with the Perfect Drycast Mould?

Selecting the right drycast mould for your concrete pipe making machine is crucial for efficient production, ensuring quality, durability and cost-effectiveness. A mismatch between the concrete pipe machine and the pipe mould can lead to defects, material waste and increased maintenance.

Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

Selecting the right pipe mould equipment is essential for producing high-quality concrete pipes. A poorly chosen mould can lead to product defects, increased maintenance costs and reduced efficiency. Many manufacturers make avoidable mistakes when selecting moulds, leading to operational setbacks.

How Drycast Technology is Changing the Concrete Pipe Industry?

The concrete pipe industry has evolved with the introduction of drycast technology, which is revolutionizing production by increasing efficiency, precision and durability. Traditional wet-cast methods required longer curing times and extensive labor, while drycast processes allow for faster, high-quality output.

Role of Concrete Pipe Machines in Canal Lining Projects

Canal lining is a fundamental aspect of water management systems, particularly in irrigation, drainage and flood control projects.

How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

Power plants stand as the core of modern civilization, transforming raw energy sources into electricity that drives industries and homes.

Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

Urban environments require a network of subterranean infrastructure to support transport systems, utility services and stormwater management.