India's rapid urbanization has placed significant pressure on its cities to modernize and build resilient infrastructure. Cities like Delhi, Mumbai, and Bangalore are witnessing unprecedented growth, which has led to increased demands for high-quality infrastructure, particularly in the areas of drainage, sewage, and transportation.

One of the most innovative technological advancements in construction that is helping meet these demands is the use of drycast mould equipment. These advanced systems play a critical role in producing durable, high-strength concrete components used in essential urban infrastructure projects, making them indispensable to modern construction in flood-prone and densely populated areas.

Understanding Drycast Mould Equipment

Drycast mould equipment refers to the machinery used in the production of concrete elements, such as pipes, manholes, U-drains, and box drains, which are crucial for urban infrastructure. Unlike traditional wet-cast methods, drycast concrete is made using a low water-to-cement ratio, creating denser, stronger, and more durable products. These products are well-suited for a variety of applications in cities, including sewage systems, stormwater management, and road infrastructure.

The use of drycast mould equipment has revolutionized the manufacturing of concrete components by improving quality, reducing curing times, and increasing overall efficiency. Among the key equipment types in drycast mould production are manhole moulds, pipe moulds, box moulds, pipe pallets, and U-drain pallets. Each of these tools plays an integral role in ensuring the production of high-quality concrete components that can withstand the test of time and environmental stress.

Key Equipment in Drycast Concrete Production

1. Manhole Mould Equipment

Manholes are essential elements in the urban sewerage system, allowing for access to underground utilities, such as water pipelines and sewage systems. Manhole mould equipment helps create robust, durable manholes capable of handling high pressure, heavy traffic loads, and the stress caused by fluctuating water levels.

These moulds are particularly important in large cities like Mumbai and Bangalore, where urban sprawl requires a continuous development of underground infrastructure to accommodate the growing population.

Manhole covers and chambers made from drycast concrete are resistant to cracking, ensuring long-lasting protection of the sewer systems. This durability reduces the frequency of maintenance and enhances the efficiency of urban drainage systems.

2. Concrete Pipe Moulds

One of the most critical aspects of infrastructure development in cities like Delhi and Mumbai is the development of efficient drainage and sewage systems. Concrete pipes are the backbone of these systems, carrying wastewater, stormwater, and other fluids throughout the city. Concrete pipe moulds are used to produce high-strength, durable pipes for these applications.

Drycast moulds are particularly beneficial in the production of concrete pipes, as they produce denser, more durable pipes than traditional wet-cast methods. These pipes are resistant to the erosion caused by constant water flow and can handle the pressure exerted by sewage and stormwater. In flood-prone areas like Mumbai, where heavy rainfall can overwhelm older drainage systems, these pipes provide an effective solution to reducing flooding and improving the efficiency of urban stormwater management.

3. Box Mould Equipment

Box drains are widely used in urban drainage systems to collect and transport stormwater. Box mould equipment is used to create rectangular or square concrete structures, which are commonly used as underground channels for stormwater. The use of box moulds allows for the creation of uniform, high-strength drainage systems that can carry larger volumes of water, thus mitigating the risk of flooding in areas with high rainfall.

In cities like Bangalore, which are subject to sudden, heavy monsoon downpours, box drains made using drycast mould equipment are essential for ensuring that excess water is quickly directed away from urban areas. These drains help prevent waterlogging and reduce the impact of floods on infrastructure.

4. Pipe Pallet Equipment

In the production of concrete pipes, pipe pallet equipment plays a crucial role in providing a stable base for curing the pipes. Once concrete is poured into the pipe moulds, these pallets support the pipes during the curing process, ensuring they maintain their shape and structural integrity. The use of pipe pallets in drycast moulding helps to streamline the manufacturing process, ensuring consistency and precision in the final product.

This equipment is crucial for large-scale urban projects in cities like Delhi, where the demand for concrete pipes is high. The faster production cycle enabled by the use of pipe pallets allows for the rapid development of drainage systems in response to urban growth.

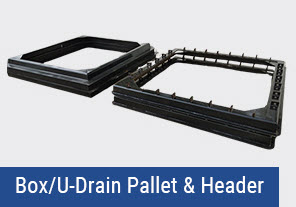

5. U-Drain Pallet Equipment

U-drains are another vital component in modern stormwater management systems. They are typically used in highways, streets, and other areas with large volumes of surface runoff. U-drain pallets are used to manufacture U-shaped concrete channels that can efficiently carry water. These drains are designed to prevent water accumulation and flooding by directing rainwater into a central drainage system.

In cities like Mumbai, where urban flooding during the monsoon season is a recurrent problem, U-drains made using drycast mould equipment provide an efficient way to manage surface runoff and prevent waterlogging. These concrete components are essential for keeping roadways and other infrastructure functional during heavy rains.

6. Header Equipment

Header equipment is used to create the end components of concrete pipes and drains. This equipment helps in shaping the headers that seal the ends of pipes, preventing leakage and ensuring a secure connection between segments of a drainage or sewage system. The strength and durability of the header equipment are crucial in ensuring the long-term stability of the entire pipeline system, especially in cities where high water pressure or seismic activity may pose challenges.

The Role of Drycast Mould Equipment in Urban Development

1. Supporting Rapid Urbanization

India’s major cities, such as Delhi, Mumbai, and Bangalore, are experiencing rapid urbanization. As the population grows, so does the demand for infrastructure that can support the needs of urban dwellers. The construction of roads, sewage systems, drainage, and water supply networks requires high-quality, durable concrete components. Drycast mould equipment is central to this effort, as it allows for the efficient and cost-effective production of the essential elements that form the backbone of urban infrastructure.

2. Durable Infrastructure for Flood-Prone Areas

India’s coastal cities, particularly Mumbai, are highly susceptible to flooding due to heavy rainfall and rising sea levels. Similarly, cities like Bangalore, with its rapid urban sprawl and increasing population density, face challenges related to water management. Drycast mould equipment helps produce durable concrete components that can withstand the stress of frequent water flow and fluctuating environmental conditions, making them ideal for flood-prone regions.

The use of concrete pipes, manholes, box drains, and other systems produced with drycast technology ensures that drainage systems are strong enough to handle extreme weather events, thereby minimizing the risk of flooding and waterlogging in cities.

3. Sustainability and Cost-Effectiveness

The use of drycast mould equipment offers significant cost savings in the production of concrete infrastructure components. The process is more efficient than traditional wet-cast methods, reducing material waste and curing time. As a result, cities can reduce the overall cost of infrastructure projects while maintaining high standards of quality and durability. This is particularly important in India, where the demand for urban infrastructure far exceeds the available budget for development projects.

Additionally, drycast concrete is highly sustainable, as it reduces water usage and requires less energy to manufacture than traditional wet-cast concrete. This aligns with India’s growing emphasis on sustainable development practices.

Conclusion

As India continues to modernize and expand its urban infrastructure, drycast mould equipment plays an indispensable role in the development of durable, cost-effective, and sustainable infrastructure projects. By supporting the production of concrete pipes, manholes, box drains, and other essential components, drycast moulds help create resilient urban systems that can withstand the challenges posed by rapid urbanization, extreme weather events, and population growth. Cities like Delhi, Mumbai, and Bangalore are well-positioned to benefit from the efficiencies provided by this technology, ensuring that their infrastructure remains functional, reliable, and future-ready.

Recent Articles

- Precast Concrete Box Culvert for Urban Underpasses and Cable Trenches

- How Concrete Pipe Machines Crucial in Power Plant Infrastructure?

- Role of Concrete Pipe Machines in Canal Lining Projects

- How Drycast Technology is Changing the Concrete Pipe Industry?

- Common Mistakes to Avoid When Selecting Pipe Moulds for Your Machine

BACK TO ARTICLES

BACK TO ARTICLES